Page 20 of 28

Re: pY Fusion Energy - Discussion

Posted: Sun May 13, 2018 12:05 am

by gosensgo86

Out of curiosity, how do fusion reactors compare to nuclear in terms of large scale production vs costs? It would be a shame to have this complex and interesting electricity production chain and not use it because it's not as viable as the vanilla options for a megabase.

Re: pY Fusion Energy - Discussion

Posted: Sun May 13, 2018 12:09 am

by pyanodon

gosensgo86 wrote:Out of curiosity, how do fusion reactors compare to nuclear in terms of large scale production vs costs? It would be a shame to have this complex and interesting electricity production chain and not use it because it's not as viable as the vanilla options for a megabase.

i never compared stuff...but 6 pyturbines running at full speed can bring 1gW easy.

Re: pY Fusion Energy - Discussion

Posted: Sun May 13, 2018 12:22 am

by kingarthur

pyanodon wrote:gosensgo86 wrote:Out of curiosity, how do fusion reactors compare to nuclear in terms of large scale production vs costs? It would be a shame to have this complex and interesting electricity production chain and not use it because it's not as viable as the vanilla options for a megabase.

i never compared stuff...but 6 pyturbines running at full speed can bring 1gW easy.

according to the wiki the base game reactor outputs 40mw per reactor + 40mw the reactor link bonus per reactor. so something like 6 reactors would give you 1gw but then you also need all the heat pipes, heat exchanges and the steam turbines. which is something like 80 odd heat exchanges and 150+ steam turbines

Re: pY Fusion Energy - Discussion

Posted: Sun Jun 03, 2018 12:04 pm

by pyanodon

Mod updated! please grab your updated version by the game or mod portal. Info on the first page.

Re: pY Fusion Energy - Discussion

Posted: Sun Jun 03, 2018 4:53 pm

by immortal_sniper1

i wander that is the input power to output power when it is compared with nuclear

Re: pY Fusion Energy - Discussion

Posted: Fri Jun 08, 2018 4:06 pm

by immortal_sniper1

i checkt the nexlite accumulators and :

Pros

they look great !

easy to know the state they are in ( charged discharging full)

neutral ponts:

same energy per tile as normal accumulators ( 1 nexelite one is as large as 4 vanilla )

better energy discharge rate ( per tile comparing with the 4 vanilla ones ) but since i plan to build loads of both this will not matter that much

cons:

with the above i will any ways build some but i am not sure if its worth building the as the primary storage (battery is easier to produce then nexelite )

and another big nail if one uses any solar enhancement mod you also get better versions of accumulators with better per tile capacity

easy fix : make 1 nexelte accumulator as good as 25 vanilla ones or have enhanced versions say X6 first one and X36 first one

Re: pY Fusion Energy - Discussion

Posted: Mon Jul 02, 2018 8:34 pm

by Raphaello

I have built industrial diamond perpetuum mobile it seems. My setup is attached.

I love diamond process by the way! there's a limited number of inputs, process is very complex but what I like the most compared to i.e. HT is that the intermediate products are not used elsewhere removing the need to belt them and the fluids. This makes the process difficult to manage and master but makes logistics on a sensible level by not requiring to belt a lot of subproducts.

Back to my setup:

- the input of kimberlite ore is cut off now - no new ore gets into the system as Grade-3 Kimberlite input is backed up

- amount of Pure Kimberlite Grade-2 is growing all the time

It seems this setup is able to produce an infinite number of diamonds from a small amount of kimberlite.

Re: pY Fusion Energy - Discussion

Posted: Mon Jul 02, 2018 8:39 pm

by steinio

You probably add power, so it's no perpetuum mobile...

Re: pY Fusion Energy - Discussion

Posted: Mon Jul 02, 2018 8:44 pm

by pyanodon

Hummmmm...i doubt its perpetuum. I need to check the recipes, but usually we dont do that mistake.

Re: pY Fusion Energy - Discussion

Posted: Mon Jul 02, 2018 9:17 pm

by Raphaello

steinio wrote:You probably add power, so it's no perpetuum mobile...

Sure, power and fluids are added but I doubt this is the intention

pyanodon wrote:Hummmmm...i doubt its perpetuum. I need to check the recipes, but usually we dont do that mistake.

It definitely work for me

I've removed all Pure Kimberlite Grade-2 from the warehouse and physically cut delivery of the ore and it still continues to build up.

Re: pY Fusion Energy - Discussion

Posted: Tue Jul 03, 2018 4:43 am

by steinio

Raphaello wrote:steinio wrote:You probably add power, so it's no perpetuum mobile...

Sure, power and fluids are added but I doubt this is the intention

pyanodon wrote:Hummmmm...i doubt its perpetuum. I need to check the recipes, but usually we dont do that mistake.

It definitely work for me

I've removed all Pure Kimberlite Grade-2 from the warehouse and physically cut delivery of the ore and it still continues to build up.

Please don't die dumb.

https://en.m.wikipedia.org/wiki/Perpetu ... biguation)

Re: pY Fusion Energy - Discussion

Posted: Tue Jul 17, 2018 4:27 pm

by immortal_sniper1

Raphaello wrote:I have built industrial diamond perpetuum mobile it seems. My setup is attached.

I love diamond process by the way! there's a limited number of inputs, process is very complex but what I like the most compared to i.e. HT is that the intermediate products are not used elsewhere removing the need to belt them and the fluids. This makes the process difficult to manage and master but makes logistics on a sensible level by not requiring to belt a lot of subproducts.

Back to my setup:

- the input of kimberlite ore is cut off now - no new ore gets into the system as Grade-3 Kimberlite input is backed up

- amount of Pure Kimberlite Grade-2 is growing all the time

It seems this setup is able to produce an infinite number of diamonds from a small amount of kimberlite.

could you please send me a BP of the entire setup

Re: pY Fusion Energy - Discussion

Posted: Tue Jul 17, 2018 7:12 pm

by Raphaello

Here you are, enjoy!

Edit: you'll need to figure out where different fluids go yourself

Re: pY Fusion Energy - Discussion

Posted: Sun Jul 29, 2018 10:38 am

by pyanodon

Mod updated! Please update your mod by mod portal or in the game.

Re: pY Fusion Energy - Discussion

Posted: Fri Sep 07, 2018 7:18 pm

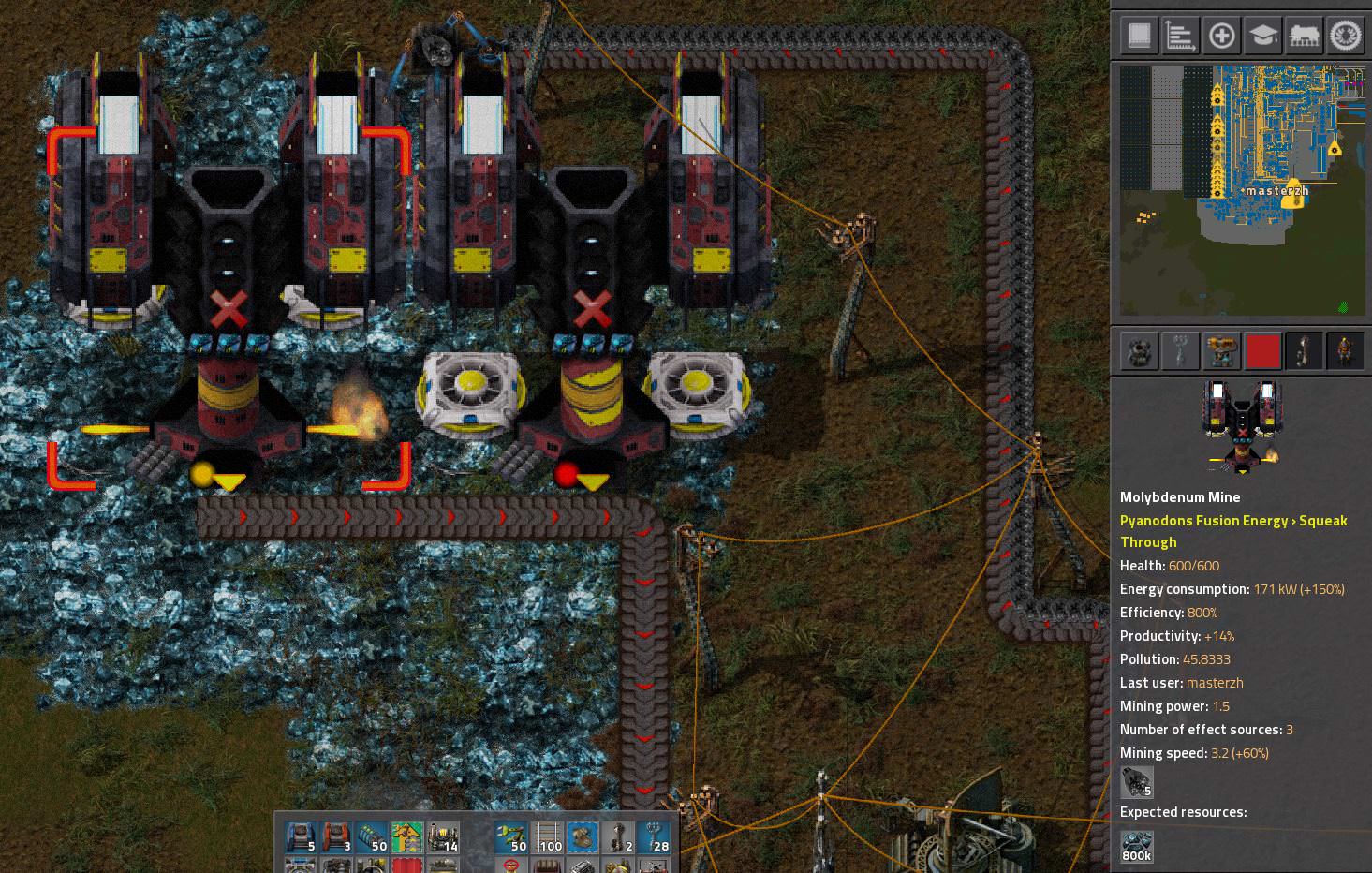

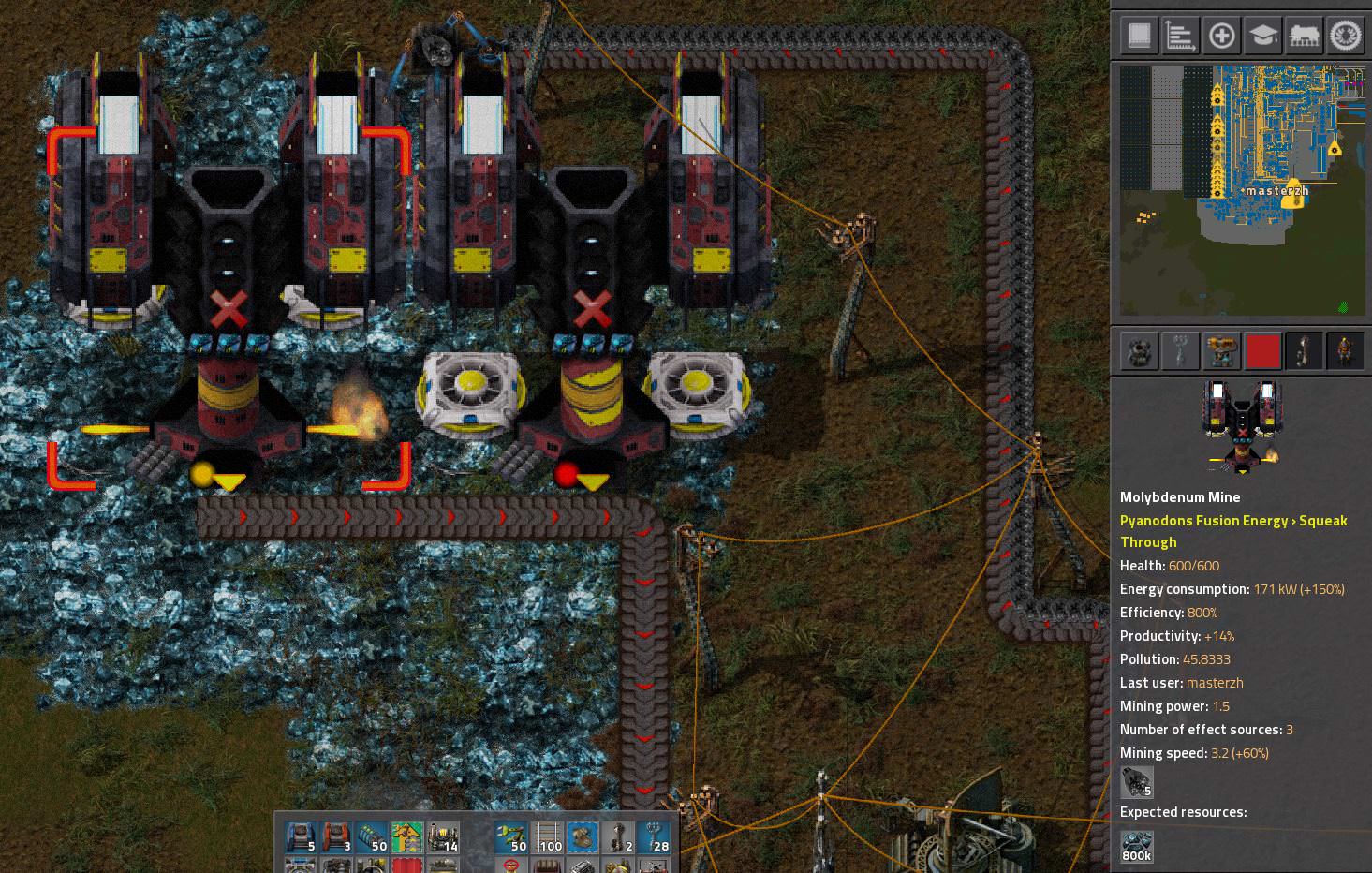

by masterzh

Hello guys, small question... my molybdenum mines keep stopping from production...

You can see they are not "done" resource wise and have more then enough drill heads... yet marked for deconstruction after some times again and again... (didnt measure how long... longer then 1hour) it can be some of my quality of life mod but i still wanted to ask. (i have all your mods are up to date)

Thank you very much !

Re: pY Fusion Energy - Discussion

Posted: Fri Sep 07, 2018 8:54 pm

by pyanodon

werid....never had that problem here. That must be some conflict between mods.

Re: pY Fusion Energy - Discussion

Posted: Fri Sep 21, 2018 11:34 am

by Mella

Where to use big counts of tungsten? There're not so many ways to use tungsten plates

May be it can be used for super alloy creating? Or may be alternative way to get cermet?

Its interesting

Approximately half of the tungsten is consumed for the production of hard materials – namely tungsten carbide – with the remaining major use being in alloys and steels. Less than 10% is used in other chemical compounds.

Hard materials

Tungsten is mainly used in the production of hard materials based on tungsten carbide, one of the hardest carbides, with a melting point of 2770 °C. WC is an efficient electrical conductor, but W2C is less so. WC is used to make wear-resistant abrasives, and "carbide" cutting tools such as knives, drills, circular saws, milling and turning tools used by the metalworking, woodworking, mining, petroleum and construction industries. Carbide tooling is actually a ceramic/metal composite, where metallic cobalt acts as a binding (matrix) material to hold the WC particles in place. This type of industrial use accounts for about 60% of current tungsten consumption.

The jewelry industry makes rings of sintered tungsten carbide, tungsten carbide/metal composites, and also metallic tungsten. WC/metal composite rings use nickel as the metal matrix in place of cobalt because it takes a higher luster when polished. Sometimes manufacturers or retailers refer to tungsten carbide as a metal, but it is a ceramic. Because of tungsten carbide's hardness, rings made of this material are extremely abrasion resistant, and will hold a burnished finish longer than rings made of metallic tungsten. Tungsten carbide rings are brittle, however, and may crack under a sharp blow.

Alloys

Further information: Tantalum-tungsten alloys

The hardness and density of tungsten are applied in obtaining heavy metal alloys. A good example is high speed steel, which can contain as much as 18% tungsten. Tungsten's high melting point makes tungsten a good material for applications like rocket nozzles, for example in the UGM-27 Polaris submarine-launched ballistic missile. Tungsten alloys are used in a wide range of different applications, including the aerospace and automotive industries and radiation shielding. Superalloys containing tungsten, such as Hastelloy and Stellite, are used in turbine blades and wear-resistant parts and coatings.

Quenched (martensitic) tungsten steel (approx. 5.5% to 7.0% W with 0.5% to 0.7% C) was used for making hard permanent magnets, due to its high remanence and coercivity, as noted by John Hopkinson (1849 - 1898) as early as 1886. The magnetic properties of a metal or an alloy are very sensitive to microstructure. For example, while the element tungsten is not ferromagnetic (but iron is), when present in steel in these proportions, it stabilizes the martensite phase, which has an enhanced ferromagnetism, as compared to the ferrite (iron) phase, due to its greater resistance to magnetic domain wall motion.

Tungsten's heat resistance makes it useful in arc welding applications when combined with another highly-conductive metal such as silver or copper. The silver or copper provides the necessary conductivity and the tungsten allows the welding rod to withstand the high-temperatures of the arc welding environment.

Armaments

Tungsten, usually alloyed with nickel and iron or cobalt to form heavy alloys, is used in kinetic energy penetrators as an alternative to depleted uranium, in applications where uranium's radioactivity is problematic even in depleted form, or where uranium's additional pyrophoric properties are not required (for example, in ordinary small arms bullets designed to penetrate body armor). Similarly, tungsten alloys have also been used in cannon shells, grenades and missiles, to create supersonic shrapnel. Germany used tungsten during World War II to produce shells for anti-tank gun designs using the Gerlich squeeze bore principle to achieve very high muzzle velocity and enhanced armor penetration from comparatively small caliber and light weight field artillery. The weapons were highly effective but a shortage of tungsten used in the shell core limited that effectiveness.

Tungsten has also been used in Dense Inert Metal Explosives, which use it as dense powder to reduce collateral damage while increasing the lethality of explosives within a small radius.

Chemical applications

Tungsten(IV) sulfide is a high temperature lubricant and is a component of catalysts for hydrodesulfurization. MoS2 is more commonly used for such applications.

Tungsten oxides are used in ceramic glazes and calcium/magnesium tungstates are used widely in fluorescent lighting. Crystal tungstates are used as scintillation detectors in nuclear physics and nuclear medicine. Other salts that contain tungsten are used in the chemical and tanning industries. Tungsten oxide (WO3) is incorporated into selective catalytic reduction (SCR) catalysts found in coal-fired power plants. These catalysts convert nitrogen oxides (NOx) to nitrogen (N2) and water (H2O) using ammonia (NH3). The tungsten oxide helps with the physical strength of the catalyst and extends catalyst life.

Niche uses

Applications requiring its high density include weights, counterweights, ballast keels for yachts, tail ballast for commercial aircraft, and as ballast in race cars for NASCAR and Formula One; depleted uranium is also used for these purposes, due to similarly high density. Seventy-five-kg blocks of tungsten were used as "cruise balance mass devices" on the entry vehicle portion of the 2012 Mars Science Laboratory spacecraft. It is an ideal material to use as a dolly for riveting, where the mass necessary for good results can be achieved in a compact bar. High-density alloys of tungsten with nickel, copper or iron are used in high-quality darts (to allow for a smaller diameter and thus tighter groupings) or for fishing lures (tungsten beads allow the fly to sink rapidly). Some cello C strings are wound with tungsten. The extra density gives this string more projection and often cellists will buy just this string and use it with three strings from a different set. Tungsten is used as an absorber on the electron telescope on the Cosmic Ray System of the two Voyager spacecraft.

Sodium tungstate is used in Folin-Ciocalteu's reagent, a mixture of different chemicals used in the "Lowry Assay" for protein content analysis.

Gold substitution

Its density, similar to that of gold, allows tungsten to be used in jewelry as an alternative to gold or platinum. Metallic tungsten is hypoallergenic, and is harder than gold alloys (though not as hard as tungsten carbide), making it useful for rings that will resist scratching, especially in designs with a brushed finish.

Because the density is so similar to that of gold (tungsten is only 0.36% less dense), tungsten can also be used in counterfeiting of gold bars, such as by plating a tungsten bar with gold, which has been observed since the 1980s, or taking an existing gold bar, drilling holes, and replacing the removed gold with tungsten rods. The densities are not exactly the same, and other properties of gold and tungsten differ, but gold-plated tungsten will pass superficial tests.

Gold-plated tungsten is available commercially from China (the main source of tungsten), both in jewelry and as bars.

Electronics

Because it retains its strength at high temperatures and has a high melting point, elemental tungsten is used in many high-temperature applications, such as light bulb, cathode-ray tube, and vacuum tube filaments, heating elements, and rocket engine nozzles. Its high melting point also makes tungsten suitable for aerospace and high-temperature uses such as electrical, heating, and welding applications, notably in the gas tungsten arc welding process (also called tungsten inert gas (TIG) welding).

Tungsten electrode used in a Gas tungsten arc welding torch

Because of its conductive properties and relative chemical inertness, tungsten is also used in electrodes, and in the emitter tips in electron-beam instruments that use field emission guns, such as electron microscopes. In electronics, tungsten is used as an interconnect material in integrated circuits, between the silicon dioxide dielectric material and the transistors. It is used in metallic films, which replace the wiring used in conventional electronics with a coat of tungsten (or molybdenum) on silicon.

The electronic structure of tungsten makes it one of the main sources for X-ray targets, and also for shielding from high-energy radiations (such as in the radiopharmaceutical industry for shielding radioactive samples of FDG). It is also used in gamma imaging as a material from which coded apertures are made, due to its excellent shielding properties. Tungsten powder is used as a filler material in plastic composites, which are used as a nontoxic substitute for lead in bullets, shot, and radiation shields. Since this element's thermal expansion is similar to borosilicate glass, it is used for making glass-to-metal seals. In addition to its high melting point, when tungsten is doped with potassium, it leads to an increased shape stability (compared to non-doped tungsten). This ensures that the filament does not sag, and no undesired changes occur.

Nanowires

Through top-down nanofabrication processes, tungsten nanowires have been fabricated and studied since 2002. Due to a particularly high surface to volume ratio, the formation of a surface oxide layer and the single crystal nature of such material, the mechanical properties differ fundamentally from those of bulk tungsten. Such tungsten nanowires have potential applications in nanoelectronics and importantly as pH probes and gas sensors. In similarity to silicon nanowires, tungsten nanowires are frequently produced from a bulk tungsten precursor followed by a thermal oxidation step to control morphology in terms of length and aspect ratio. Using the Deal–Grove model it is possible to predict the oxidation kinetics of nanowires fabricated through such thermal oxidation processing.

Re: pY Fusion Energy - Discussion

Posted: Fri Sep 21, 2018 11:57 am

by pyanodon

Tungstein isnt part of my mods.

Re: pY Fusion Energy - Discussion

Posted: Fri Sep 21, 2018 2:56 pm

by aklesey1

pyanodon wrote: ↑Fri Sep 21, 2018 11:57 am

Tungstein isnt part of my mods.

Are u sure? U're using it in blanket recipe, in Regolite mine, in Centrifugal Pan, in Compressor

I'm agree with Mella for most part let's think where we can use it wonderful metal

very informative help about tungsten

Re: pY Fusion Energy - Discussion

Posted: Fri Sep 21, 2018 3:08 pm

by pyanodon

Tungstein is from bobs and the mod adapt it when avaiable. But it isnt in my plans since you can see theres no W in the pyores poll.